Convenience plastic moulding

We inject a wide variety of plastic parts ranging in weight from a few milligrams to 8 kilograms in the full range of commodity resins: polypropylene (PP), polyethylene (LLDPE, HDPE, HMWPE) and polystyrene (PS, HIPS).

We manufacture many products where colour is critical to the aesthetics of the finished product. This is why we have developed a particular expertise in the moulding of coloured parts.

COMPETITIVELY PRICED RAW MATERIALS

We are able to generate buying power to obtain the best prices on the base resins used to manufacture your plastic parts. Our silo system allows us to purchase and store materials in large quantities. Our good business relationship with our material suppliers gives us the operational flexibility to benefit our customers.

PRODUCTIVITY AND FLEXIBILITY

We design and manufacture the moulds in-house. Our team can optimise the design and thickness of the part and the process parameters to reduce cycle time. We can also use additives combined with commodity resins to minimize injection time. In addition, a manufacturing software for injection moulding informs us in real time of the status of each machine, speeding up the team's reaction time.

WIDE RANGE OF COLOURS

We produce plastic parts to your specific color code (Pantone or other). All colors can be created, including opaque and translucent ones. A spectrophotometer (colorimeter) measures color and provides data on deviations. Contact us to discuss your customized options.

Engineering and reinforced resin moulding

At VIF, we have many years of experience in custom plastic injection moulding. As expert consultants, we can guide you in choosing the best engineering resin to use depending on the function of your part and the characteristics required.

Whatever the design or performance you want to give your product, we have a turnkey solution, no matter how much you need to produce. The right resin is important to give the desired mechanical properties, be it strength, UV resistance, malleability, etc.

RANGE OF ENGINEERING AND REINFORCED RESINS

We have a wide range of resins for plastic injection moulding: polycarbonate (PC), polyvinyl chloride (PVC), polyamide (nylon), acrylonitrile butadiene styrene (ABS), acetal (POM), elastomers (TPE, TPV), thermoplastic polyurethane (TPUR), thermoplastic polyolefin (TPO, TEO), polyphenylene ether (PPE), acrylic (PMMA), SBS and all alloys (ABS+PA, ABS+PC, PC+PET, PC+PBT). We can also mould all resins available on the market.

WIDE RANGE OF COLOURS

We produce plastic parts to your specific color code (Pantone or other). All colors can be created, including opaque and translucent ones. A spectrophotometer (colorimeter) measures color and provides data on deviations. Contact us to discuss your customized options.

ALL EXPERTISE IN-HOUSE

With many years of experience in plastic injection moulding, we know every type of engineering resin and its associated characteristics. In order to save you time and money on your production, we will suggest equivalent raw materials at lower costs but with the same quality. Reduce your part weight and cycle time with the right resin for your product.

Precision moulding

As mold experts and specialists in precision molding, we can help you choose the right material (commodity or engineering resin) for your plastic injection parts.

Whether your industry is consumer goods, recreational products, materials handling or anything in between, we'll work with you to develop a custom mold design, the right process for your project, and the right design for the functionality of your plastic part.

DESIGN AND PROCESS

With VIF Plastiques, you get precision molding thanks to a design that respects very high tolerances, for all our types of operation including plastic-plastic overmolding, multicolor molding, molding with metal insert, overmolding with soft touch application, and more. Our rigorous PDP- and APQP-based processes, combined with high levels of equipment maintenance, mean you get a finished product that meets your requirements. Presses with clamping forces ranging from 40 to 2,000 tons are at your disposal for the manufacture of all your parts.

VERIFICATION OF THE PART IN PRODUCTION

To ensure consistent quality and better productivity, your parts can be measured by verification tools such as CMMs and other measuring jigs. Depending on your needs, we can offer vision systems installed on each robot cell, measuring tolerances of plus or minus 0.1 mm. Be assured of a flawless product with validation at every stage.

Multi-material moulding

At VIF Plastiques, we specialize in multi-material injection moulding for companies in Quebec, Ontario and the Northeast. With expertise in the field developed since the late 1990s, we can advise you on the choice of materials to obtain the best combination.

As expert consultants, we can guide you through the right multi-material moulding process according to your budgets and annual volumes. For small, medium or large volumes, we have a solution to reduce the amount of plastic used and the production time.

PLASTIC-PLASTIC OVERMOULDING

Whatever your sector of activity, we can handle all types of plastic-on-plastic moulding. It is possible to mould different plastic resins, compatible or not by chemical or mechanical bonding. Several cells are available for plastic-on-plastic moulding.

For small volumes, we can make a manual transfer from one press to another, while the operation can be robotized for medium volumes. For very large volumes and depending on your needs, we offer several alternative solutions and are open to equipping ourselves specifically for your project. Contact us to find out how we can help.

Overmoulding

We offer you customised overmoulding solutions in all fields: construction, automotive, security, medical, handling, etc. Take advantage of all the expertise under one roof for the overmoulding of your plastic-metal parts or overmoulding on mechanical components.

Overmoulding allows you to reduce your production costs by reducing assembly time, the number of secondary operations and the amount of product in your inventory. In order to maximize the yield of your finished product, it is imperative to choose the right type of plastic to obtain the right properties. We will guide you in the most economical and optimal choice of raw material.

PLASTIC-TO-METAL OVERMOULDING

For any particular industrial request, VIF is flexible and adapts to your requirements by innovating and designing customised plans for your project.

While some of our injection moulding machines are equipped with robots to increase reliability, all of them allow the overmoulding of plastic around a metal insert or parts made of brass, aluminium, steel, electronic chips (for RFID applications), etc. This overmoulding technique combines the robustness of a metal with the different properties of the plastic resins used.

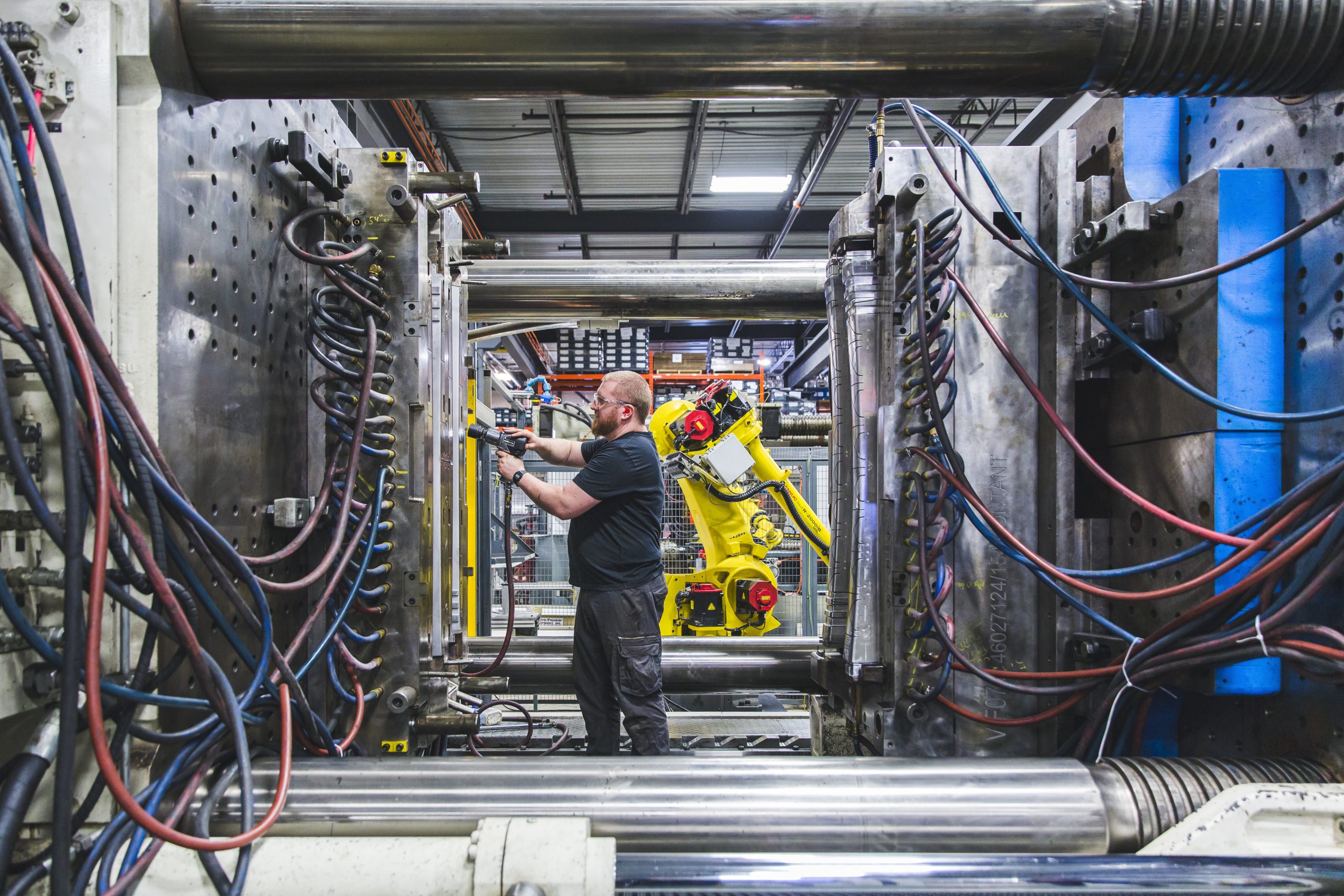

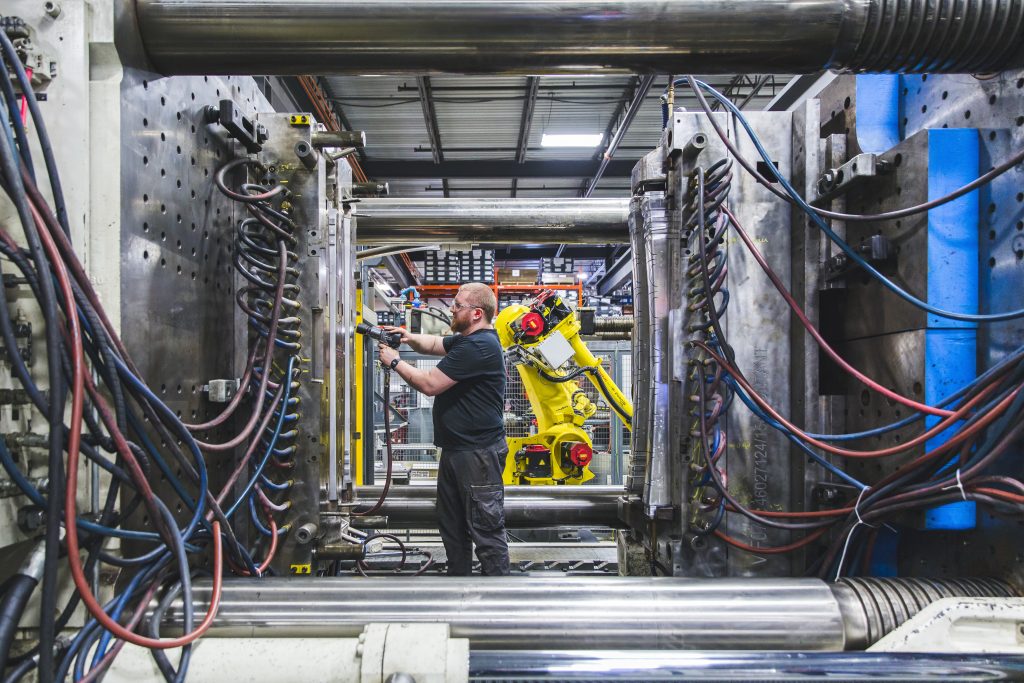

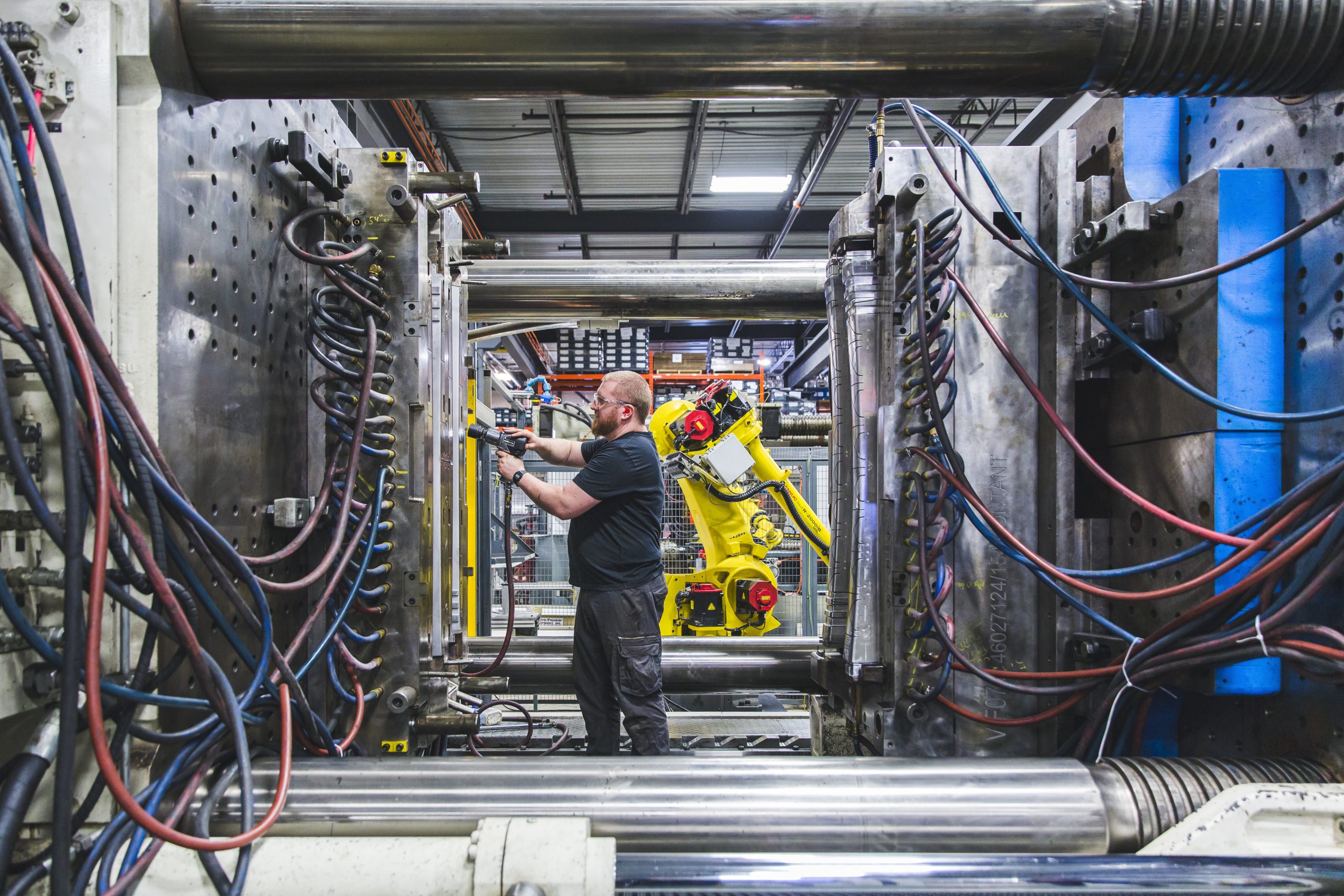

ROBOTIZATION OF THE PROCESS

We can robotize and automate a cell to increase productivity during overmolding operations. We can also install inspection systems to ensure 100% part quality.

IN-MOULD LABELLING (IML)

We inject a wide variety of plastic parts ranging in weight from a few milligrams to 8 kilograms in the entire range of materials. As a multi-technology company, we can overmould labels (in-mold labeling - IML) during plastic injection molding. Regardless of the size of your mould, your logo, decorative element or inserted text can be combined with several complex colours.

Visually, in-mould labelling is the most aesthetically pleasing form of printing and offers great flexibility in design. Achieve substantial savings and reduce secondary handling and gluing operations.

HIGH RESISTANCE

As the label is inserted into the mould, it is impossible to remove it. This feature is increasingly required in the market for security purposes and ensures a high level of quality and resistance to scratching, peeling and general wear and tear. Protection against solvents and chemicals can also be added. In addition, IML is more resistant to harsh storage environments (humidity, cold, etc.).